Why Screen Ratio and Resolution Matter for Industrial Touch Screen Monitors

The Impact of Screen Ratio on Operational Efficiency

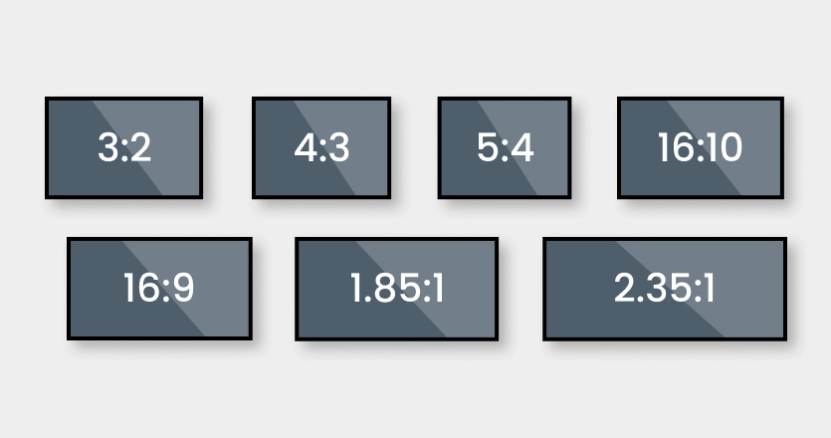

Screen ratio plays a crucial role in the efficiency of industrial operations. Different screen ratios cater to specific workflows, enhancing usability and performance. The 4:3 ratio is commonly used in legacy systems and applications requiring a more square-shaped display. The 16:9 widescreen format is popular for real-time monitoring systems, offering better visibility for dashboards and control panels. Some industries require custom ratios, such as ultra-wide screens for conveyor belt monitoring or compact square screens for space-limited environments

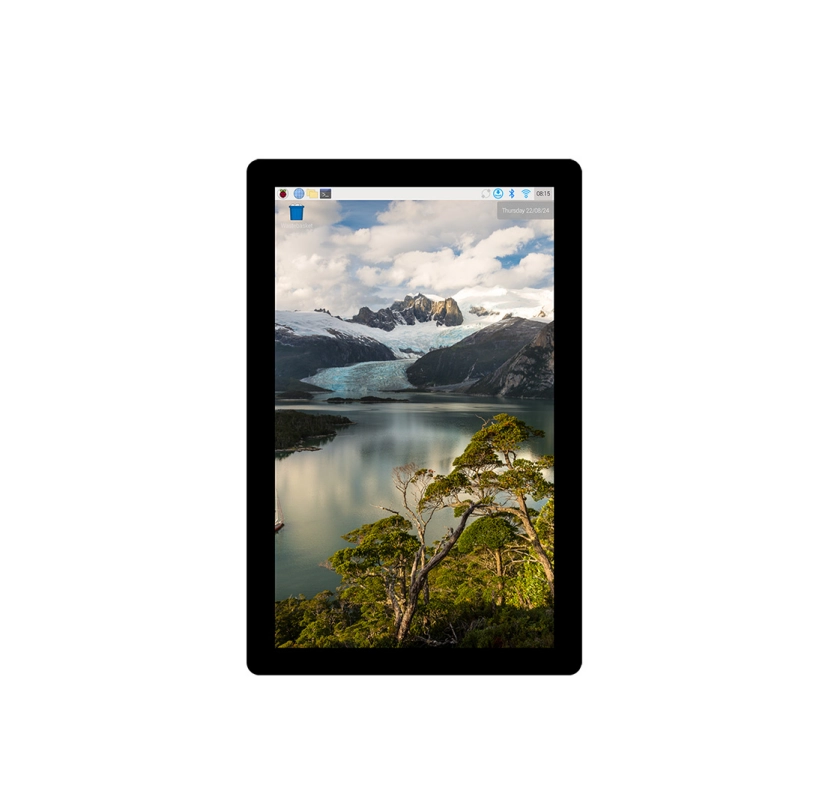

A manufacturing example underscores screen direction’s value. One plant adopted upright screens for equipment updates. Workers swiftly reviewed key details with minimal motion. In contrast, flat layouts in command centers offered a wider perspective across several activities. This aided prompt choices. Picking an apt screen ratio fosters smooth task blending and cuts interruptions.

Resolution Requirements for Industrial Environments

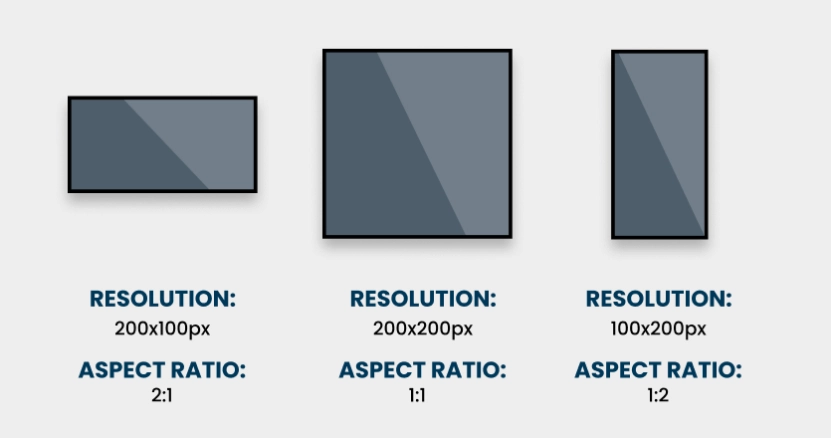

Resolution greatly shapes display sharpness and legibility in industrial zones. Yet, opting for the top resolution doesn’t always yield peak results. Dense pixels sharpen visuals but may tax processing strength and raise power use. For industrial purposes, toughness traits matter too. These include sunlight visibility, dust proofing, and glare-reducing layers alongside resolution.

Many believe 1080p is ideal. However, this varies by need. Outdoor shipping screens, for example, gain more from bright, lower-resolution panels that curb glare. On the other hand, complex design tasks in automation might call for sharper 2K or 4K clarity. Striking a harmony between vividness and practicality ensures steady, lasting performance.

Key Factors to Evaluate When Choosing an Industrial Monitor and Touch Screen

Environmental Demands and Screen Durability

Industrial monitors endure tough settings, like scorching heat or dust and dampness exposure. IP-rated displays shield against such risks, promising durability in rough areas. Touch screens built for industrial use boast strengthened glass, impact toughness, and coatings to lessen reflections.

Top industrial touch screen manufacturers craft items with sturdy casings and materials. These resist physical strain. Sectors like mining, marine, and car production gain from screens with broad temperature tolerance. Such designs keep running smoothly even in harsh climates.

Touch Technology Compatibility

Selecting apt touch tech hinges on usage. Resistive touch screens suit gloved settings, such as food handling or chemical sites. Capacitive ones deliver sharp accuracy and multi-touch options. They’re perfect for intricate automation controls. Infrared touch panels shine where contact-free operation is key, like sterile rooms or healthcare spaces.

Future-Proofing with Scalable Resolutions

Industrial tech advances swiftly. Choosing a screen with adjustable resolution curbs outdatedness. Automation, IoT merging, and AI-driven tools now push for sharper visuals and flexible displays. A monitor ready for future enhancements offers enduring worth and aligns with new tech.

Matching Screen Ratios to Industrial Applications

16:9 for Real-Time Data Visualization

The 16:9 widescreen setup thrives in industrial control hubs and watch systems. This format grants a broad viewpoint. Operators can track multiple data flows at once. In shipping and transit, 16:9 screens enhance GPS mapping and stock viewing in warehouses.

Square Ratios (4:3, 5:4) for Legacy Systems

Aging industrial setups often stick to 4:3 or 5:4 displays for software fit. Many older ERP tools and machines were built for these shapes. Widescreen styles don’t work as well here. A square-ratio monitor keeps integration smooth without pricey tweaks.

Custom Ratios for Niche Industrial Touch Screen Panels

Certain fields need tailored screen sizes and ratios. Ultra-wide displays aid conveyor belt systems with sweeping process views. Compact screens in robotics maximize space while offering precise data. Custom ratios ensure industrial touch screen panels meet unique demands without excess trade-offs.

Balancing Resolution and Performance in Industrial Settings

High Resolution vs. Processing Power Trade-offs

High-resolution screens yield excellent image quality. Yet, they demand more computing muscle. In industrial zones, where quick response is vital, too much resolution can lag systems. For instance, a 4K display in a plant control hub might overdo it if staff only need clear text and simple shapes. A fitting resolution avoids undue hardware stress while keeping tasks efficient.

Low-Light vs. High-Brightness Scenarios

Different industrial spots need varied brightness. High-brightness screens boost readability outdoors, such as in mining or building sites. Meanwhile, low-light-friendly displays ease eye strain in round-the-clock control rooms. Tuning resolution and glow to the setting lifts usability and lifespan.

Reducing Eye Strain in 24/7 Operations

Staff in industrial roles often face screens for long stretches. Weak resolution and poor refresh rates tire eyes. Displays with good contrast, glare-proof coatings, and tuned resolution cut fatigue. They enhance sustained use. Choosing a mix of resolution and user-friendly design lifts comfort and work rate.

How to Identify Reliable Industrial Touch Screen Manufacturers

Certifications That Guarantee Quality

Certifications like NEMA, UL, and MIL-STD confirm industrial monitors hit safety and toughness marks. NEMA ratings show dust and water defense. UL approval ensures electrical safety. MIL-STD tests prove resistance to jolts, shakes, and extreme heat or cold. Verifying these marks aids firms in picking trusty industrial monitors.

Customization vs. Off-the-Shelf Solutions

Industrial needs often call for bespoke screen fixes. Off-the-shelf monitors may suffice for basic uses. However, custom industrial touch screen panels allow pairing with special gear and programs. Kadi Display provides an industrial touch screen monitor customization service. This ensures fit with distinct industrial wants.

Evaluating Long-Term Support and Warranty

Beyond upfront price, ongoing aid and warranty from a maker matter greatly. Trustworthy industrial touch screen manufacturers offer long warranties, fixes, and updates. This keeps monitors running years on. Choosing a maker with solid lifecycle care cuts downtime and lasting costs.

Industry Trends Shaping Screen Ratio and Resolution Choices

The Rise of Adaptive Resolution Technology

AI-powered displays grow common in industrial uses. These screens tweak resolution and brightness based on user tasks and surroundings. This lifts efficiency and sight. Adaptive resolution tech proves especially handy in automation and smart production.

Sustainability in Industrial Monitor Design

Eco-friendly displays gain ground as firms seek green options. Industrial monitors now use low-energy parts, recyclable materials, and clean production ways. Picking sustainable screens trims power bills and eco-harm while keeping top performance.

FAQs: Industrial Touch Screen Monitor Selection

What’s the best industrial touch screen monitor for high-vibration environments?

Choose ruggedized panels with toughened glass and shock-dampening mounts.

Can I upgrade an existing industrial monitor and touch screen setup?

Yes, but check compatibility with current software and power needs.

How do I clean an industrial touch screen panel without damaging it?

Use gentle cleaners and microfiber cloths. Avoid alcohol-based mixes.

Are higher-resolution screens always better for industrial applications?

Not always. Prioritize readability and system speed over raw specs.

Finding the ideal screen ratio and resolution for your industrial needs proving tough? Reach out to Kadi Display today. Explore how our skill in industrial touch screen tech can streamline your work. Learn the perks of our Kadi Display industrial touch screen monitor customization service—where fresh ideas meet dependability.