Why are Industrial Displays Essential in Harsh Environments?

In the realm of industrial applications, displays serve a crucial function, particularly when situated in harsh environments. These displays must withstand not only environmental elements such as dust, moisture, and extreme temperatures but also deliver reliable performance and readability. Industries such as manufacturing, oil and gas, and mining require displays that can endure rigorous conditions while delivering accurate information in real-time. Ultimately, the right industrial display can prevent operational downtime and ensure safety in challenging environments.

What Factors Make a Good Industrial Display?

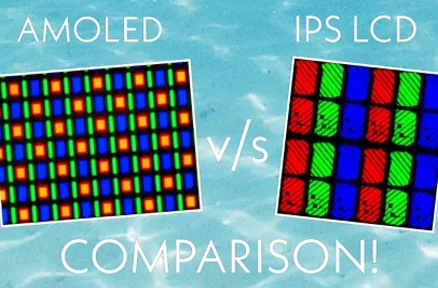

Choosing an industrial display goes beyond aesthetics; it incorporates various critical considerations, including durability, resolution, and responsiveness. A quality display should not only offer high-resolution imagery but also ensure a long lifespan in rugged settings. Key characteristics include the display’s ability to operate continuously under adverse conditions, low energy consumption, and the ability to interface smoothly with different types of equipment. As technology evolves, customization options have become invaluable, enabling organizations to tailor displays to specific operational requirements.

How Does Temperature Tolerance Impact Display Performance?

Temperature tolerance is vital when assessing an industrial display’s performance. Displays subjected to extreme heat or cold can suffer from degraded performance, failure, or even complete shutdowns. Manufacturers often provide temperature specifications to ensure that their displays can handle the expected environmental conditions. Therefore, selecting a display rated for both high and low temperatures ensures operational reliability, alongside smooth functionality throughout various working scenarios. Understanding these specifications can help in making informed decisions that support long-term success.

Key Features to Look for in Industrial Displays

Is Visibility Maintained Under Different Lighting Conditions?

Having visibility is crucial when choosing screens for different environments that can have changing light conditions. Features like glare tech and high brightness levels play a key role in ensuring clear access to information. High-brightness screens perform outdoors where sunlight might cause visibility issues. It’s important to make sure the screen remains clear and intact when faced with varying conditions to boost operational efficiency.

Are Touchscreen Options Reliable in Difficult Conditions?

Touchscreen displays are widely used in today’s settings due to their convenience and versatility. However, it is crucial to ensure their durability under circumstances is proven reliable and withstands potential issues such as water and dust exposure while maintaining precise input recognition in adverse environmental conditions without compromising touch sensitivity in extreme situations for seamless operator interaction with the interface.

Material Considerations

What Materials Ensure Long-lasting Durability?

When creating a display the choice of materials is crucial for its durability and efficiency over time. Resilient materials that can withstand impacts scratches and corrosion are essential. Generally, displays are made of toughened glass or special coatings that improve their robustness. Additionally, metal enclosures are commonly employed to provide strength and ensure the display can endure treatment and impacts often encountered in environments.

Environmental Ratings: Why They Matter?

When choosing screens or monitors for use in settings and conditions, it’s important to consider the environmental ratings assigned to them. These ratings act as signals of the product’s durability and performance capabilities offering users insights into how the display can function in diverse environmental situations and ensuring that it complies with industry standards and needs.

What Do IP Ratings Indicate about a Display?

The rating system known as Ingress Protection (IP) plays a role in assessing the ability of a display to withstand dust and moisture infiltration effectively. A higher IP rating signifies resistance. For instance, an IP67 rating indicates the display is fully sealed against dust and capable of surviving immersion. This aspect holds importance in industries exposed to environmental conditions since it bolsters durability and safety measures.

Are Other Certifications Important?

In addition to IP ratings, more certifications may be relevant depending on the application’s specific requirements. Certifications like MIL-STD for military-grade models or Atex approval for hazardous environments provide assurances regarding the display’s performance in challenging conditions. Assessing these certifications before selection safeguards both the investment and safety of personnel using the equipment.

In conclusion, selecting an appropriate industrial display for extreme environments requires careful consideration of multiple factors. Kadi Display offers an exhaustive range of industrial displays, tailored to meet the unique demands of various applications. With over 20 years of experience, we are committed to delivering customized LCD solutions, including advanced touch and PCBA options to ensure seamless integration into your projects. Our dedicated R&D team and modern manufacturing practices ensure high-quality products designed to withstand the rigors of extreme environments. You can learn more about our offerings by visiting Kadi Display.

Connectivity and Integration

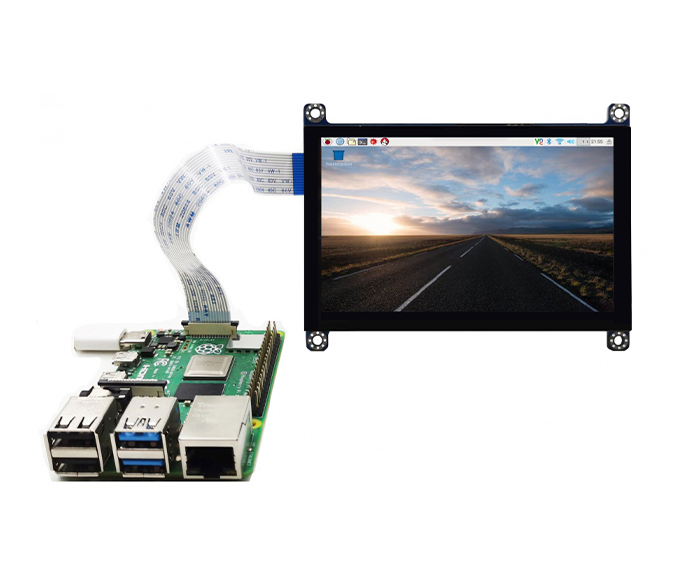

How Do Connectivity Options Influence Selection?

When choosing a screen for your workspace setup in action settings is crucial to consider the connectivity options available for operations to take place effectively and efficiently. Environments in industrial sectors may call for various connection methods depending on the structures and machines involved. It’s important to be aware of the communication protocols they use. For example, some systems may need HDMI or DisplayPort links while others rely on LVDS or MIPI interfaces.

Additionally incorporating features into screens introduces another dimension of connectivity choices facilitating instant data transfer and remote surveillance. Ensuring the compatibility, with systems ensures communication through the display thereby sustaining operational productivity. Inadequate connections may result in prolonged periods of inactivity or necessitate expensive alterations underscoring the importance of evaluating the required connection types and verifying their presence in display units.

Will the Display Integrate Seamlessly with Existing Systems?

Having a screen that can easily work with systems is important for keeping operations smooth and efficient flow intact. A good display should be able to blend in with the existing setup without requiring changes. If it’s not compatible enough, it can create issues where information doesn’t transmit properly or interfaces become less responsive to users’ needs resulting in frustration among operators.

Moreover, screens with customization options can make integration simpler as users have the flexibility to adjust pin configurations or settings to match existing systems Collaborating with companies like Kadi Display who specialize in customized solutions can ensure that expected integration needs are fulfilled. An integrated screen system boosts efficiency and delivers information crucial for making decisions in fast-moving settings.

Maintenance and Support Considerations

What are the Maintenance Requirements?

Understanding the maintenance needs of displays is crucial before choosing since these displays are subjected to use in tough conditions. A regular check-up and cleaning routine are usually required to prevent damage from dust moisture and wear and tear from the operation. The way maintenance is done can differ based on whether the displays are placed in mild environments. For instance, a display that is exposed to chemicals or extreme temperatures may need inspections and quick action to reduce the risk of malfunction.

Moreover,know the layout of a screen can help make maintenance tasks easier. Use screens with parts that can be easily replaced or accessed for cleaning. This way, you will spend time on repairs and upkeep. Businesses need to evaluate maintenance needs carefully before choosing a screen. This can ensure performance and dependability in the run.

How Essential is Service Support from Manufacturers?

The after-sales assistance offered by companies can greatly influence the sustainability of screens over time. Quality customer service should cover help with setting up the displays troubleshooting advice and prompt responses to any problems that arise. Businesses need to assess the support provided by manufacturers to guarantee operations without disruptions.

Timely Manufacturer support plays a role in scenarios requiring technical help to prevent possible downtime situations from occurring smoothly and to maintain operations uninterrupted for customers in need of assistance when facing challenges—a reputable service provider such as Kadi Display can significantly impact the availability of expertise when needed the most by ensuring quick and effective customer support services after sales through clear service agreements and warranty provisions that guarantee ongoing support and resource accessibility for continuous operations.

Conclusion

In conclusion, the journey of selecting the right industrial display for use in extreme environments requires a methodical approach considering various factors. These market-ready displays must provide resilient connectivity options and seamless integration capabilities, maximizing operational efficiency. Regular maintenance requirements and robust service support from manufacturers contribute to long-term reliability and overall satisfaction.

Kadi Display stands as a leader in addressing these needs, delivering tailored solutions across various display technologies to meet the demands of rugged environments. Our commitment to service excellence, combined with a wealth of industry experience, positions us as a preferred partner for businesses seeking to enhance their operations with dependable industrial displays. By focusing on customization, durability, and user-centered design, we strive to support client needs effectively in diverse applications. For comprehensive insights into our diverse offerings, consider visiting Kadi Display, where innovative display solutions await to align with your organization’s needs.