Industrial touch screens are the backbone of modern manufacturing, automation, and a variety of industrial processes. These robust displays are built to resist the most unfriendly environments, but even the most resilient screens can fall prey to wear and tear, malfunction, and occasional damage.

Understanding Industrial Touch Screens

While smartphones and tablets boast sleek displays, the screen on an industrial touch screen is more about durability and functionality. They are built to operate in extreme conditions:

Rugged Enclosures:with rugged enclosures, often bearing an IP rating to specify the resistance of the unit against dust and liquids that protects sensitive electronics from environmental hazards.

Robust Touch Panels: Unlike consumer touch screens that emphasize thinness and sensitivity, industrial touch screens make use of thicker, more robust touch panels, which are able to withstand repeated touches, bumps, and vibrations. This resilience ensures reliable operation in demanding industrial settings.

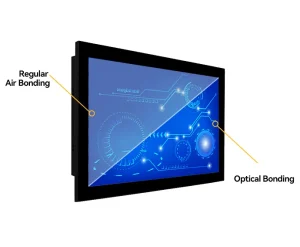

Anti-glare Coatings: Glare from either sunlight or artificial lights reduces visibility in industrial settings. Most industrial touch screens have anti-glare coatings to address the problem and enhance clear vision, reducing operator fatigue.

Wider Operating Temperatures: Compared to consumer products, industrial touch screens support a wider temperature range for operation. This makes them very suitable for extreme conditions in factories where temperatures may either be extremely high or low, and outdoor applications.

Common Industrial Touch Screen Defects and Troubleshooting

Identifying the specific problem is vital for effective repair and minimizing downtime. Below are common touch screen defects, their possible causes, and troubleshooting tips for industrial applications:

1. Cracked Screen

A cracked screen is one of the most visible and common issues that may arise with industrial touch screens. While this is often caused by external impact or mishandling, it can also occur over time due to wear and tear in high-traffic environments.

Cause: Cracks usually occur due to physical impact, excessive pressure, or temperature fluctuations that cause the screen to expand or contract.

Troubleshooting: Unfortunately, the cracked screen is usually irreparable. The best solution is replacing the whole touch screen unit. When replacing, ensure the new screen is well calibrated to prevent future damage. It is very important to handle the screen with care during installation and not impose extra stress on it.

2. Unresponsive Touch

A touch screen that doesn’t respond to user input is a frustrating issue, especially in industrial settings where downtime can be costly. Unresponsiveness can stem from various causes:

Cause 1: Software Glitch

Troubleshooting: Software glitches can often make touch screens stop responding to inputs. Begin by restarting the system or recalibrating the touch screen. Many industrial touch screens are designed with built-in diagnostic tools that can help in identifying software-related problems. If the problem persists after recalibration, updating or reinstalling the touch screen drivers or the entire operating system may help restore functionality.

Cause 2: Faulty Digitizer

Troubleshooting: It is the digitizer that translates these touches into a language understood by the system. Thus, any damages to or malfunction of the digitizer would cause the screen to stop registering touches. Usually, this is due to hardware failure; thus, replacement of the defective digitizer will be the course of action.

Cause 3: Loose Connections

Troubleshooting: Touch screens cannot deliver the signals if the cables are not properly connected or have disconnected. Check all the cables that are connected to a touch screen controller for their security. Also, examine cables and connectors visible for any damage and replace if there is any. At times, the re-seating or reconnecting the cables properly resolves the issue.

3. Ghost Touches

Ghost touches refer to the touches that touchscreen detects and are not made. These are disruptive, and could make the system respond in unpredictable ways or execute undesired actions.·

Cause 1: Electromagnetic Interference (EMI)·

Troubleshooting: Since industrial environments have a lot of EMI, this could be a factor that may cause malfunctioning with touch input. Make sure that the touch screen system is properly grounded and shielded. Use EMI shielding materials and check for any irregularities in the power supply. Proper grounding reduces interference and maintains consistent touch response.

Cause 2: Software Issues

Troubleshooting: Ghost touches can be caused by outdated or corrupted touch screen drivers. Make sure the drivers are updated from the manufacturer’s website or through software updates. Reinstall the touch screen drivers if necessary to resolve the problem.

Cause 3: Failing Touch Controller

Troubleshooting:This is the module that converts the touch inputs into something understandable by the system. When it is malfunctioning, the screen registers spurious touches. In some instances, the only way out is to replace it. It may require specialized tools to diagnose the controller; therefore, a professional technician may need to be consulted or the touch screen manufacturer contacted.

4. Calibration Issues

Calibration issues refer to situations where the touch input isn’t aligned with the cursor or display, making accurate screen interaction by users difficult. This is particularly critical in industrial applications where precision may be of essence.

Cause: The causes can be due to changes in temperature, power interruptions, and software corruption.

Troubleshooting: Most industrial touch screens have some kind of calibration tool set up within their settings. Run the calibration process by usually tapping specific points on the screen to align the touch input with the cursor. If it is not resolved by re-calibration, then a software reset or even a system update may be required.

5. Dim or Flickering Display

A dim or flickering screen makes reading the information that appears on the touch screen difficult, which may cause operations to slow down in industrial settings.

Cause 1: Backlight Failure

Troubleshooting: The backlight lights the screen. If the backlight isn’t working, the screen is going to be really dim or even black completely. First, check backlight settings, and second, the power feeding to the backlight is intact. Otherwise, one may need to replace the backlight assembly in case this doesn’t resolve.

Cause 2: Loose Connections

Troubleshooting: Your display may have loose or damaged cables, which is the problem of turning off power to your display for showing dim or flickering. Check for wear or damage in the display cable and power connections. Ensure that all connections are snug, and replace any damaged cables. Checking the power supply and ensuring that it is stable can also help.

Cause 3: Display Driver Issues

Troubleshooting: Display driver issues can cause the screen to flicker or dim. Make sure that the display drivers are updated. If updating doesn’t work, try reinstalling the drivers or replacing the display hardware if the problem persists.

6. Physical Damage

Physical damage like scratches, cracks, or damaged connectors can also render the touch screen unit malfunctioning.

Cause: This could be from mishandling, jolts from accidents, or even harsh environments. The slightest crack or damaged cable can make a touchscreen not work.

Troubleshooting: Scrutinize the whole touchscreen unit, the cables, connectors, and the screen for any signs of damage. Replace immediately any damaged parts to avoid other problems. When the screen shows cracks or scratches, the whole screen replacement might be necessary to keep it functional.

Preventive Measures to Extend Touch Screen Lifespan

You can actually extend the lifespan of your industrial touchscreen by implementing the following preventive measures, thus reducing the frequency and cost of repairs:

Environmental Control: Maintaining a clean and temperature-controlled environment around the touch screen minimizes dust buildup and protects it from extreme temperatures.

Proper Handling Techniques: Train operators on proper touch screen handling, emphasizing the use of styluses for extended interactions, avoiding forceful touches, and keeping the screen free of liquids and debris.

Regular Cleaning: Implement regular screen cleaning protocols using appropriate solutions to remove dust and fingerprints without damaging the anti-glare coating.

Protective Measures: Consider installing screen protectors or protective enclosures to safeguard against accidental impacts and scratches.

Periodic Maintenance: Schedule routine maintenance checks to inspect cables, connections, and overall system functionality to address minor issues before they become major problems.

Kadi Display: A Reliable Solution for Industrial Touch Screens

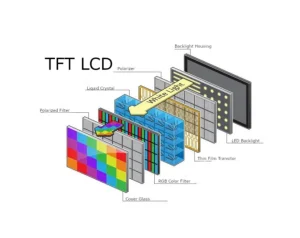

Kadi Display is a well-established display manufacturer with over two decades of industry experience. From the diversified display technologies of OLED, TFT LCD, and HDMI/DSI, their expertise is channeled to meet the needs of diversified industries. Kadi Display has been committed to providing professional guidance and tailored products for their customers’ requirements and is dedicated to quality and to the resolution of challenges at every stage of their projects. They provide technical support during all phases of a project, ensuring timely and effective support.

For those applications that demand a tough and reliable touchscreen display, Kadi Display 10.1-inch 1280×800 industrial-grade TFT LCD display with CTP is highly suitable. The display has a resolution of 1280×800, an LVDS interface, and a brightness of 800 nits. Moreover, during the manufacturing process, Kadi Display uses AOI to ensure quality and stability in their displays. They inspect for conductive particles in critical components like the IC and FPC with great care, guaranteeing long-term reliability.