What is an HMI Touch Screen Panel and Why Does Picking the Right One Matter?

HMI (Human-Machine Interface) touch screen panels are vital instruments in industrial automation. These devices act as a link between workers and equipment. They enable people to oversee activities, tweak configurations, and react to live information. You’ll find them in sectors like production, power generation, transport, and beyond, where accurate oversight and management are critical.

Opting for the perfect HMI panel is highly important. A poor choice might cause setbacks, prolonged interruptions, and steeper repair expenses. For instance, a panel unsuited to tough surroundings could break down when faced with dirt, dampness, or severe heat. Issues with integration can also pop up if the panel doesn’t align with current programs or connection methods. Putting resources into a suitable HMI panel guarantees steady workflows. It also boosts output and cuts future costs.

5 Crucial Elements When Picking an HMI Touch Screen Panel

Environmental Sturdiness & Industrial Approval

Industrial settings frequently subject gear to intense situations, like shifting temperatures, shaking, and chemical contact. Choosing an HMI panel with proper safeguarding ratings promises durability and dependability. Panels boasting elevated IP scores fend off dust and moisture. Meanwhile, reinforced builds shield against knocks. Approvals such as CE, UL, and ISO show that a panel meets safety and efficiency benchmarks.

Display Clarity and Touch Precision

A top-notch HMI panel should feature a sharp screen with ample clarity to show intricate details without tiring the user’s eyes. Bright screens are vital for outdoor use. Plus, glare-resistant layers enhance visibility under strong light. Touch accuracy matters too for ease of use. Capacitive screens provide exact handling but might falter with gloves. On the other hand, resistive screens work well in damp or gloved conditions.

Harmony with Current Setups

HMI panels need to blend effortlessly with industrial management systems. They must support connection standards like Modbus, PROFINET, and Ethernet/IP to link with PLCs, detectors, and other automated tools. A panel that doesn’t match existing setups might demand costly changes or swaps. Reviewing software and driver availability beforehand ensures smooth setup.

Expandability and Long-Term Viability

Industrial automation keeps advancing. Thus, picking an HMI panel that adjusts to upcoming demands is key. Some units provide software updates and flexible builds for simple enhancements. Linking with IoT systems grows more significant too. This allows distant tracking and forward-looking upkeep. Choosing an adaptable HMI panel avoids outdatedness. It also secures a lengthier usability span.

Assessing China HMI Touch Screen Panel Factories

Many buyers turn to China HMI touch screen panel factories for affordable rates and cutting-edge production skills. Manufacturers there offer diverse tailoring choices, swift sample creation, and large-scale output abilities. Teaming up with a dependable provider grants access to superior goods at fair prices. Performing factory checks, verifying credentials, and studying buyer reviews aids in finding a reputable maker.

Innovative Shifts Influencing HMI Panel Choices in 2025

Growth of Multi-Touch and Motion Commands

Today’s HMI panels are evolving past basic touch features. Multi-touch options let users enlarge, slide, and engage with the layout more smoothly. Some high-tech setups even include motion commands. This cuts down on physical touching in delicate fields like healthcare and food handling.

Edge Processing Inclusion

With Industry 4.0 on the rise, plenty of HMI panels now handle edge processing. These units manage data on-site, lessening reliance on steady cloud links. As a result, responses speed up, data use drops, and security strengthens. Edge-ready HMI panels shine in tasks needing instant data review, such as robotic assembly lines and power tracking systems.

Eco-Friendliness in Production

As ecological rules tighten, makers are leaning toward greener methods. Many China HMI touch screen panel providers now use reusable resources and power-saving parts to lessen their footprint. Diminished-power screens and earth-friendly wrapping add to sustainable automation answers. Firms that value eco-consciousness enjoy reduced energy bills and a stronger public image.

A Step-by-Step Approach to Evaluating HMI Panels

On-Location Trial Runs

Before rolling out an HMI panel in a work setting, testing its ability in lifelike scenarios is crucial. Mimicking factors like moisture, grit, and jolts confirms the panel can endure real challenges. On-site trials pinpoint possible hiccups before widespread use.

Endurance Strain Checks

Industrial HMI panels run nonstop, often lasting years without swaps. Running strain tests that mimic prolonged use in varied states helps gauge the panel’s staying power. Aspects like screen fade, touch consistency, and part wear need checking to promise lasting trustworthiness.

User Input Cycles

Folks like equipment handlers and technicians should join in testing HMI panels. Their thoughts on ease, speed, and layout design offer useful hints for picking the best fit. Ensuring the panel suits work needs lifts task flow and trims learning time.

Why Tailoring Counts (and When to Weigh It)

Sector-Specific Demands

Various fields have distinct needs for HMI panels. In healthcare, units must hit cleanliness marks and provide spot-on touch accuracy. Car-making tasks call for tough builds and resistance to heat swings. Picking an HMI panel crafted for niche field wants ensures peak results.

The Value of Kadi Display HMI Touch Screen Panel Customization Service

Kadi Display, based in Shenzhen, delivers tailored HMI answers for industrial and health uses. The firm emphasizes toughness, rule-following, and smooth blending. Customization covers screen sizes, interface tweaks, and branding touches to match unique workflows. Kadi Display’s skill in industrial touch tech assures dependability and ongoing help.

FAQs About HMI Touch Screen Panels

What’s the typical lifespan of a China HMI touch screen panel?

With good care, most industrial HMI panels endure five to seven years. Surroundings like heat, wetness, and use frequency affect longevity.

Can I update older gear with new HMI panels?

Yes, but matching with current control setups is vital. Checking connection standards and software fit avoids hitches.

How do I confirm a China HMI touch screen panel factory’s quality?

Asking for credentials like ISO 9001, CE, and UL verifies production norms. Factory tours or third-party reviews add further confidence.

Are toughened panels worth the added price?

In rough settings, sturdy HMI panels cut down on frequent swaps and reduce pauses. They guard better against bumps, wet, and harsh heat.

Ready to Boost Your HMI Plan?

Choosing the ideal HMI touch screen panel is pivotal for automation triumph. A smartly picked panel lifts output, secures workflow smoothness, and trims future expenses. If you seek trusty options, Kadi Display provides expert advice and top-tier industrial screens. Reach out Kadi Display today to talk over your project needs and check out our HMI touch screen panel customization service. Let’s shape the next wave of industrial automation together.

Latest Blog & News

- How to Choose the Best HMI Touch Screen Panel

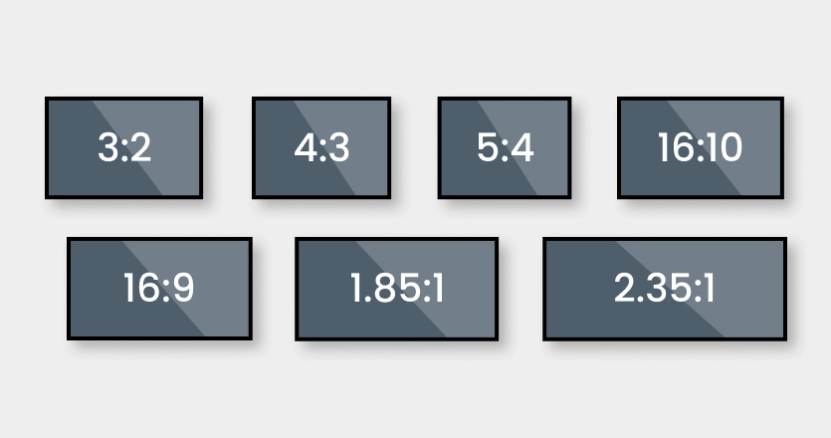

- How to Select the Right Screen Ratio and Resolution for Industrial Touch Screens and Monitors

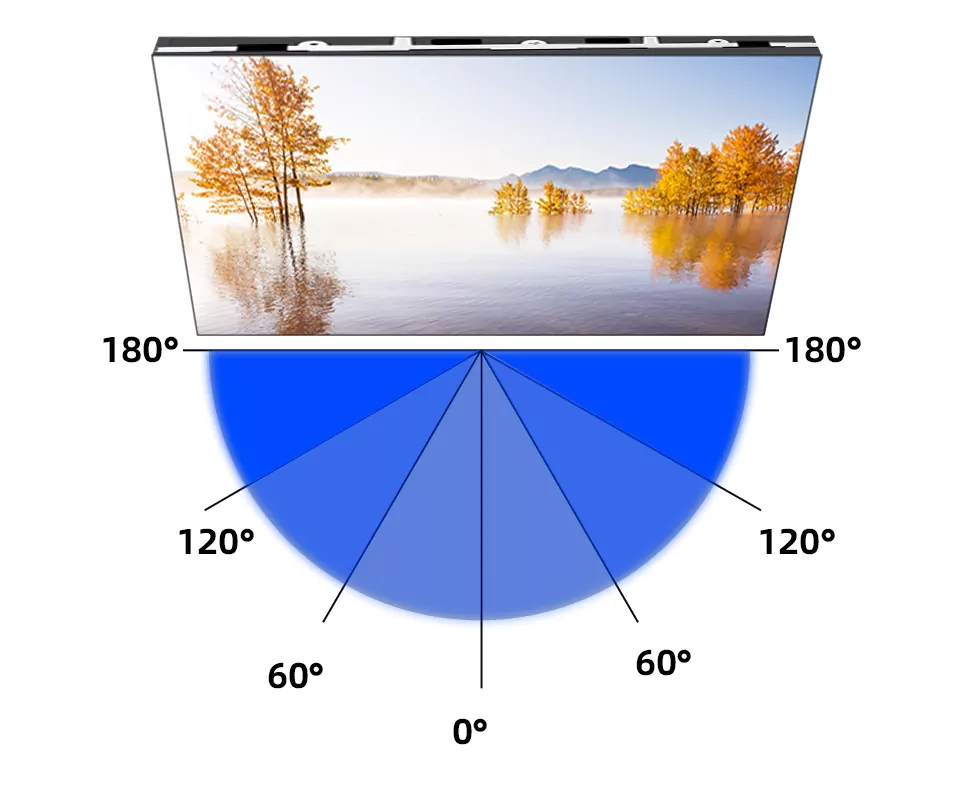

- How to Distinguish the Viewing Angles of LCD Displays

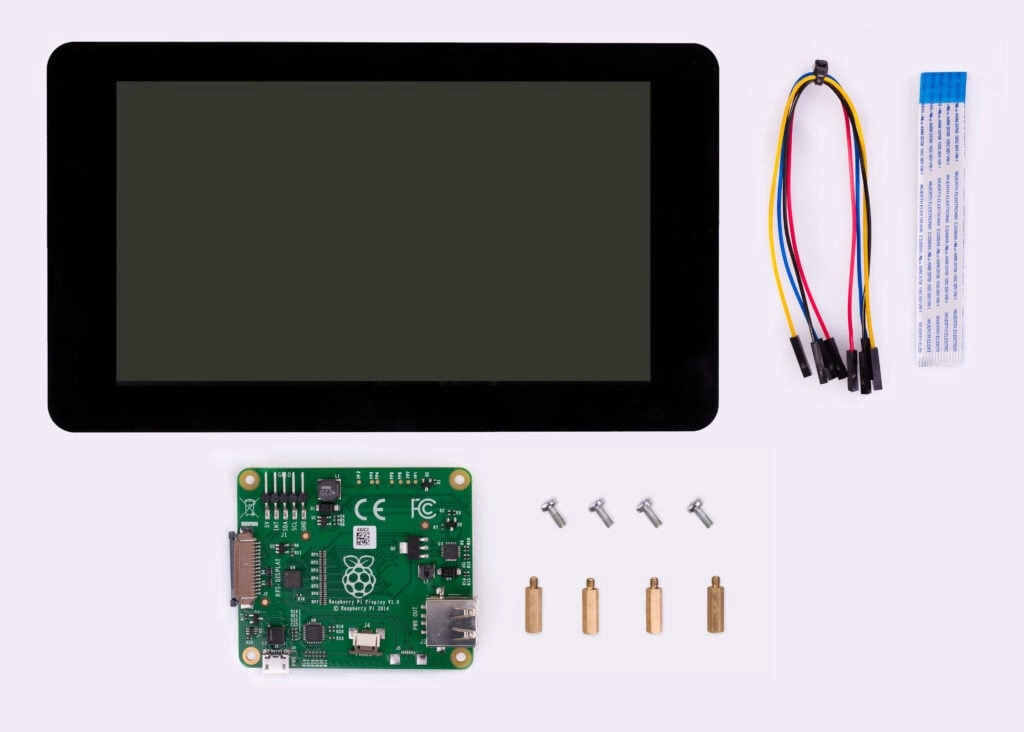

- Tips for Using Touch Screen OLED Display for Raspberry Pi

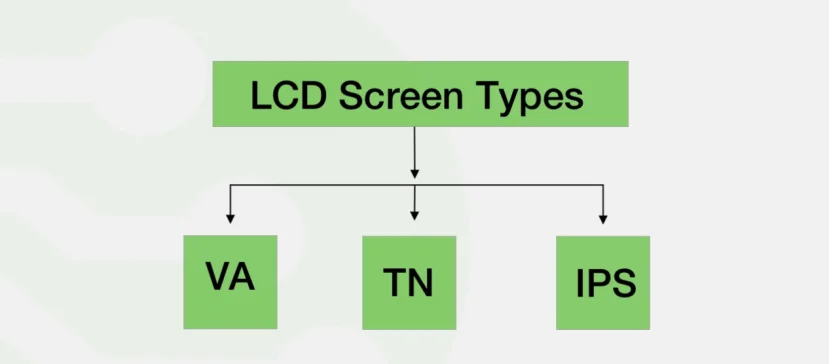

- OLED vs IPS LCD Display: Which Screen Technology Is Better?