Introduction to Bonding Technologies in TFT Touch Screens

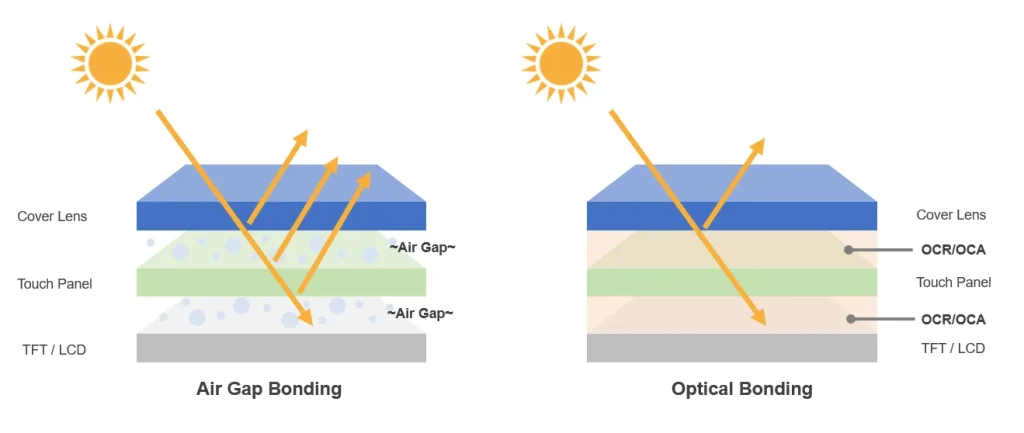

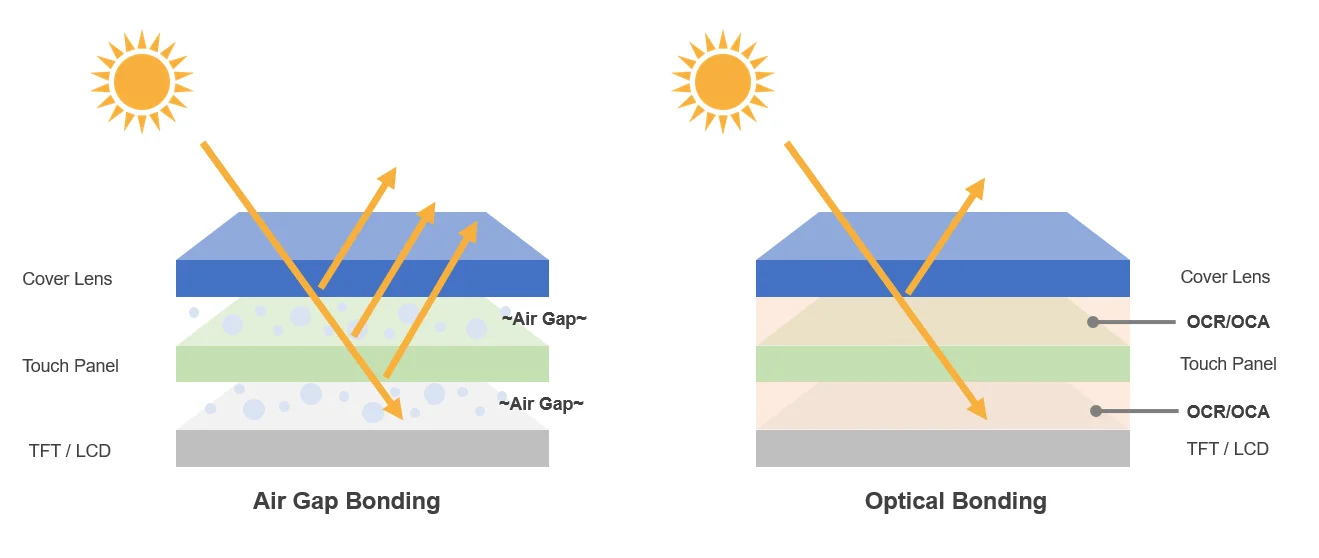

In the realm of TFT touch screens, bonding technologies play a crucial role in enhancing display performance and durability. Among these technologies, air bonding and optical bonding stand out as two prevalent methods. Understanding the nuances between these techniques is essential for making informed decisions regarding display manufacturing and application.

Understanding Air Bonding (Air Gap Bonding)

Definition and Process

Air bonding, also called air gap bonding, means sticking the touch panel to the display with glue just around the edges. This leaves a tiny air space between the layers. Lots of people use this way because it’s simple and doesn’t cost much.

Advantages of Air Bonding

A big plus of air bonding is it’s cheaper to make than other ways. The steps are straightforward. You need fewer supplies too. Also, air bonding makes it easy to fix or swap parts since the layers aren’t stuck together for good.

Limitations of Air Bonding

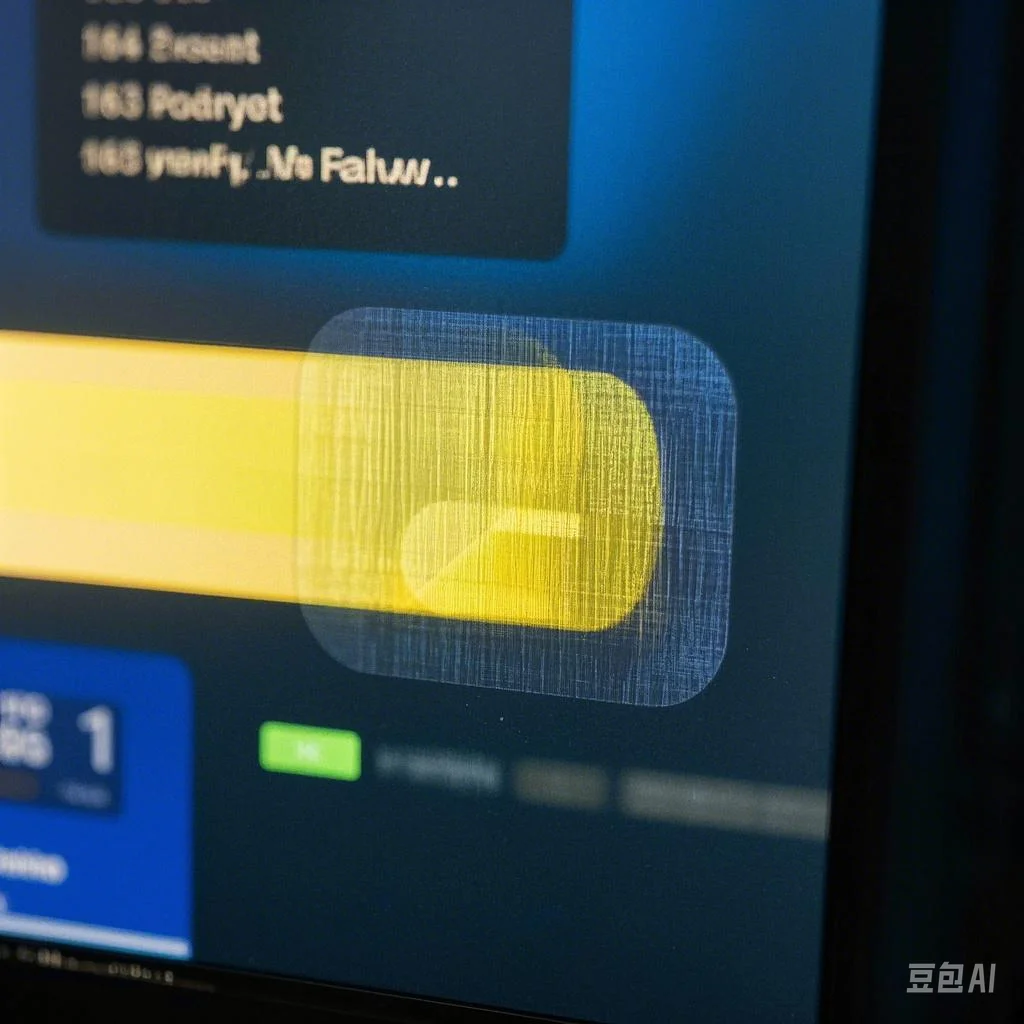

Even with its low price, air bonding has downsides. That air space can blur the screen and bounce more light back, making it tough to see in bright places. Over time, the gap might catch dust or water. This could hurt how long the display lasts or how well it works.

Exploring Optical Bonding

Definition and Process

Optical bonding uses a clear glue or resin to fill the space between the touch panel and display. It wipes out any air gaps by joining the layers tight. You get a smooth connection with this method.

Advantages of Optical Bonding

Optical bonding really steps up how the screen looks. It cuts down glare and boosts contrast. No air gap means fewer light bounces inside, so you see better even in full sun. Plus, it keeps out dust and water, making the display tougher for the long haul.

Challenges of Optical Bonding

Optical bonding has perks, but it’s got hurdles too. The process takes more work. You need exact glue or resin use, which bumps up costs. Fixing bonded parts is tricky since they’re locked together for good.

Key Differences: Air Bonding vs. Optical Bonding

Optical Performance

How clear the screen looks varies a lot between these two. Optical bonding gives sharp views with less shine thanks to its no-gap setup. Air bonding, though, can fuzz up the picture. The air space causes light to bounce inside.

Environmental Resistance

When it comes to handling the outdoors, optical bonding wins. Its tight seal blocks dust and water from sneaking in. Air bonded displays let stuff creep through the edges into the gap, so they’re weaker against the elements.

Long-Term Reliability

Staying solid over time is where optical bonding shines. No openings for dirt or damp keep these displays strong. Air bonded ones might wear down if junk builds up in the gap.

Cost-Benefit Analysis

Cost-wise, air bonding saves money at the start. But it might cost more later if the weather messes it up. Optical bonding asks for more cash upfront. Its toughness and better looks can make it worth it for jobs needing top trust.

Kadi Display offers custom optical bonding TFT touch screens services and custom air bonding TFT touch screens services tailored to fit what you need. They keep quality and performance high for all kinds of uses across industries.

Applications: Where Each Bonding Method Excels

Optical Bonding in Medical and Industrial Screens

Optical bonding works great where clear screens and toughness matter most. In medical spots, where exact data is a must, bonded screens show true images. No glare or inside light bounces mess things up. The tight join also cuts the chance of dirt sneaking in, key for clean spaces.

In industrial jobs, screens face rough stuff like dust, water, and hot or cold shifts. Optical bonding makes them sturdier. They hold up against harsh settings. Better sight in bright sun or strong lights helps workers read clear and decide smart.

Niche Uses for Air Bonding

Optical bonding might top the charts, but air bonding fits where cash beats fancy screen needs. Gadgets like tablets and basic smartphones often go with air bonding. It’s cheaper to make. A little less clear screen is okay for the price.

Also, air bonding’s easy fixes suit short-life products or ones that get quick updates. Makers can swap parts without big hassle or cost. It works for markets that churn out new stuff fast.

Choosing the Right Bonding Method for Your Project

Factors to Consider

Picking the best bonding way means weighing a few things. Think about where it’ll be used, how much you can spend, and what screen quality you want. For jobs needing tough builds and great sight in hard spots, optical bonding often wins despite the price. If cash is tight or needs are simpler, air bonding’s low cost helps.

How long the product lasts matters too. Optically bonded screens stay trusty with less upkeep since they fight off weather stuff. But if it’s short-lived or gets lots of updates, air bonding’s fix-friendly side could tip the scale.

Custom Solutions by Kadi Display

Contact Kadi Display for customizing optical bonding TFT touch screen services and customizing air bonding TFT touch screens services built for your project’s needs across all sorts of fields. They tweak solutions to keep quality and performance spot-on, giving clients displays that fit just right.

FAQs

What are the main differences between air bonding and optical bonding?

Air bonding leaves an air gap with glue around edges. Optical bonding uses clear glue for a no-gap layer. This changes clarity and weather strength.

Which method offers better optical performance?

Optical bonding beats out with clearer views and less light bounce thanks to no air gap.

How do these methods compare in terms of environmental resistance?

Optically bonded displays guard better against dust and water with their tight seal. Air bonded ones let stuff slip into gaps through edges.

Is there a significant cost difference between these methods?

Yep, air bonding costs less to start but might add upkeep costs from weather wear. Optical bonding takes more cash first but pays off with toughness in tough jobs.

Can I choose a custom solution for my project?

Sure thing—Kadi Display crafts solutions just for your needs, keeping top quality and performance across industries.

Latest Blog & News

- What is the difference between air bonding and optical bonding in TFT touch screens?

- A Complete Guide to TFT Display Interfaces: RGB,LVDS, MIPI,HDMI & More

- What Causes LCD Burn in and How Can You Prevent It?

- How to choose the Best Stretched Bar LCD Monitors for Your Business

- The Role of Open Frame Touchscreen Monitors in Industrial HMI Automation