Open frame touchscreen monitors are part of today’s industrial automation and an interface centerpiece for Human-Machine Interface (HMI) systems. Open frame touchscreen monitors, which are not typically housed, leave their internal parts exposed to the environment, therefore easily integrable into industrial setups. With touchscreen technology, the system can be operated directly, resulting in enhanced operating efficiency and management.

In industrial environments, HMI systems bridge the gap between equipment and operators, enabling real-time equipment control and feedback such as temperature, pressure, and machine status. The connection between open frame touchscreen monitors and HMI automation is so critical because the monitors serve as the visual interface through which the operators engage with the industrial processes, which tend to be complex.

The Importance in Modern Industries

Open frame touchscreen monitors serve a significant purpose in a variety of industries. They are utilized in factories on the assembly line for the display of production instructions, quality, and inventory levels. In the manufacturing of cars, productivity was enhanced by 20% or higher with the use of these monitors because employees had real-time access to important information, thereby making efficiency more productive.

In power stations and oil refineries, among others, open frame monitors enable operators to monitor real-time data on energy output, equipment health, and safety procedures, reducing response time by 30%. In the medical field, monitors are being used in patient monitoring systems, enabling access to vital signs and treatment schedules with greater ease, thereby improving patient care.

Technical Specifications of Open Frame Touchscreen Monitors

Open frame monitors use a number of touch-sensing technologies:

Resistive Touch: Pressure-sensitive, the technology can be controlled using styluses or gloves and is very accurate but susceptible to scratches and less sensitive to gentle touches.

Capacitive Touch: Exploits the electrical nature of the human body, providing high sensitivity and multi-touch but bare skin contact.

Surface Acoustic Wave (SAW) Touch: Offers touch sensing through ultrasonic waves, providing clear images and durability, but can be affected by dirt and humidity.

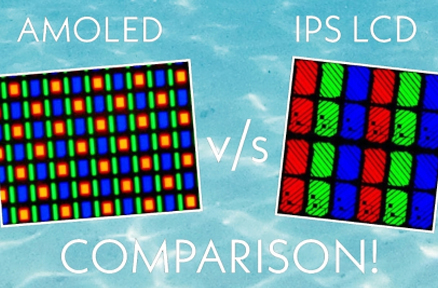

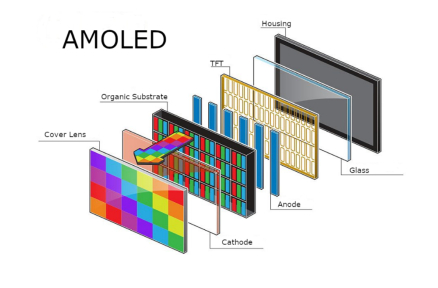

The display technologies employed are Liquid Crystal Displays (LCD) and LED-backlit LCDs, which are power-saving high-quality displays. LED-backlit LCDs are utilized in industrial applications since they offer increased brightness, contrast ratios, and longevity.

Function in HMI Systems

Open frame touchscreen monitors play a fundamental role in HMI systems by communicating touch input to the software application. For instance, when an operator adjusts a value, the touch-sensing feature of the monitor transfers the signal to the controller, where the input is received and the machine is adjusted accordingly. It enables real-time adjustment of processes, such as adjusting the conveyor belt speed or altering production parameters.

Key Benefits in Industrial HMI Automation

Enhanced User Experience

The interfaces are user-friendly, allowing even lesser experienced operators to manage complex industrial processes. Studies have discovered that operators of touchscreen HMIs learn to use them in 2-3 days, unlike the long learning curve of the previous systems. The high-definition display also prevents human error through increased readability, lowering defects by 15-20% in vision-based tasks.

High Customization Potential

Open frame touchscreen monitors can be customized to a large extent to suit the specific requirements of diverse industries. In aerospace, for example, ruggedized monitors are built to withstand severe environments, and in mining, dust-proof and water-resistant monitors increase equipment uptime by up to 30%. HMI software can also be tailored for bespoke data visualization to help improve process control and efficiency.

In a chemical plant, custom HMI software with real-time chemical reaction data in a simple-to-report graphical format saved 10% in energy consumption. Such alterations enable monitors to be resistant to harsh environments and to simplify industrial process.

Space-Saving and Flexible Installation

Open frame touchscreen monitors offer space-saving configurations and mounting versatility that make them well-suited for broad industrial applications. With open-frame designs, they are easy to mount into existing control panels, or on an arm or wall. At one small electronics factory, for example, monitors were mounted over the assembly line to save desktop space while placing viewing angles at operators’ fingertips.

They also see application in large industrial plants. They may be installed in numerous locations in power plants, e.g., control rooms for monitoring and mobile cart units for point-of-use repair. This portability enhances operational efficiency, as seen in a power plant where this procedure cut response time to equipment failure by 25%.

Cost-Effectiveness in the Long Run

While open frame touchscreen monitors are more expensive upfront, they save money in the long term. They require less maintenance because they are reliable and last longer. For instance, one packing plant reduced its five-year maintenance expense by 40% by using high-quality open frame monitors. Failure of hardware and wear and tear on the touchscreen reduced, requiring less replacement.

These displays also increase productivity, which leads to cost savings. In an automobile assembly line, their usage sped up the process, leading to a 15% increase in car production per day. This increase in productivity translated into greater revenues. In addition, energy-efficient technologies use less electricity and are hence more cost-effective over time.

Applications in Various Industries

Manufacturing

Open frame monitors ease production procedures in manufacturing. They do away with paper-based guides, and examples include:

At an automobile factory, workers access assembly guides and quality control details in real-time. This boosts efficiency and reduces mistakes, saving a 15% defect decrease within the first year.

Energy industry

In the energy sector, they are at the core of oil refinery and power plant operations. In a power plant, their application by the operators to interpret equipment parameters like pressure and temperature guarantees smooth operations and prevention of failures through preventive control. Similarly, oil and gas operation utilizes remote monitoring stations that utilize open frame monitors to monitor the pipeline conditions, enhancing efficiency and safety.

Transportation and logistics

In transportation and logistics, open frame monitors simplify processes on material handling equipment and in control centers. In an airport, for example, air traffic controllers use them to monitor flight schedules and locations of aircraft, so the airport operates more efficiently and reduces delays. In logistics, forklifts with them have reduced loading and off-loading times by 20%, raising customer satisfaction and saving funds.

Challenges and Solutions

Open frame touchscreen monitors struggle in hostile environments such as dust areas and water exposure. Dust and water entry in industrial use such as coal mining or beverage bottling factories can damage the monitors. The manufacturers address these challenges by developing dust-resistant coatings and IP-rated enclosures to keep the monitors out of reach of dust and water.

Long-term reliability is an issue. Frequent use wears out the screen and degrades parts in the long term. Improving reliability, monitors are manufactured with scratch-resistance materials like Gorilla Glass and high-quality parts with better heat dissipation. Regular maintenance and replacement cycles for the parts guarantee the long-term reliability.

Compatibility with older systems is a principal issue. Industrial plants for the most part use older communication protocols incompatible with new monitors. Middleware and adapters can help in this area by facilitating communications between old and new systems without any interruption. Software development kits (SDKs) also help integrate the monitors into installed software environments.

Conclusion

Open frame touchscreen monitors are now of central importance in industrial HMI automation. Their simple, adjustable look and advanced functions significantly promote efficiency, safety, and productivity in various industries from manufacturing to energy and transport. Despite the issues, the monitors offer long-term benefits, thus a valuable investment for industries.

Kadi Display, with two decades of expertise, specializes in high-performance touchscreen monitors and display solutions for industrial automation. Kadi Display open-frame touchscreen monitors enhance HMI efficiency, offering durability, precision, and seamless integration. Optimize your operations with Kadi Display’s advanced technology. Contact us today to elevate your industrial display solutions!

Latest Blog & News

- A Complete Guide to TFT Display Interfaces: RGB,LVDS, MIPI,HDMI & More

- What Causes LCD Burn in and How Can You Prevent It?

- How to choose the Best Stretched Bar LCD Monitors for Your Business

- The Role of Open Frame Touchscreen Monitors in Industrial HMI Automation

- TFT LCD Screen vs AMOLED: Which Technology Is Best for Your Business?